Quality System

At CoPower, quality management is more than a process - it's the only way we do business. Our approach to integrate systematically from design stage to delivery of production, is highly effective. Our early participation improves the customer's design for manufacturability and reliability. We apply AQP (Advanced Quality Planning) for standards and procedures to identify the quality requirements of each project before manufacturing begins. Additionally, the FMEA (Failure Mode Effects Analysis) and production control plans are prepared to identify the potential failure mode and possible trouble spots during production. We use SPC (Statistical Process Control) to monitor manufacturing processes that results in higher produce quality.

CoPower has a strict testing system for checking incoming materials, in-house procedure controls and end-product testing. We keep detailed records of inspection data for every order.

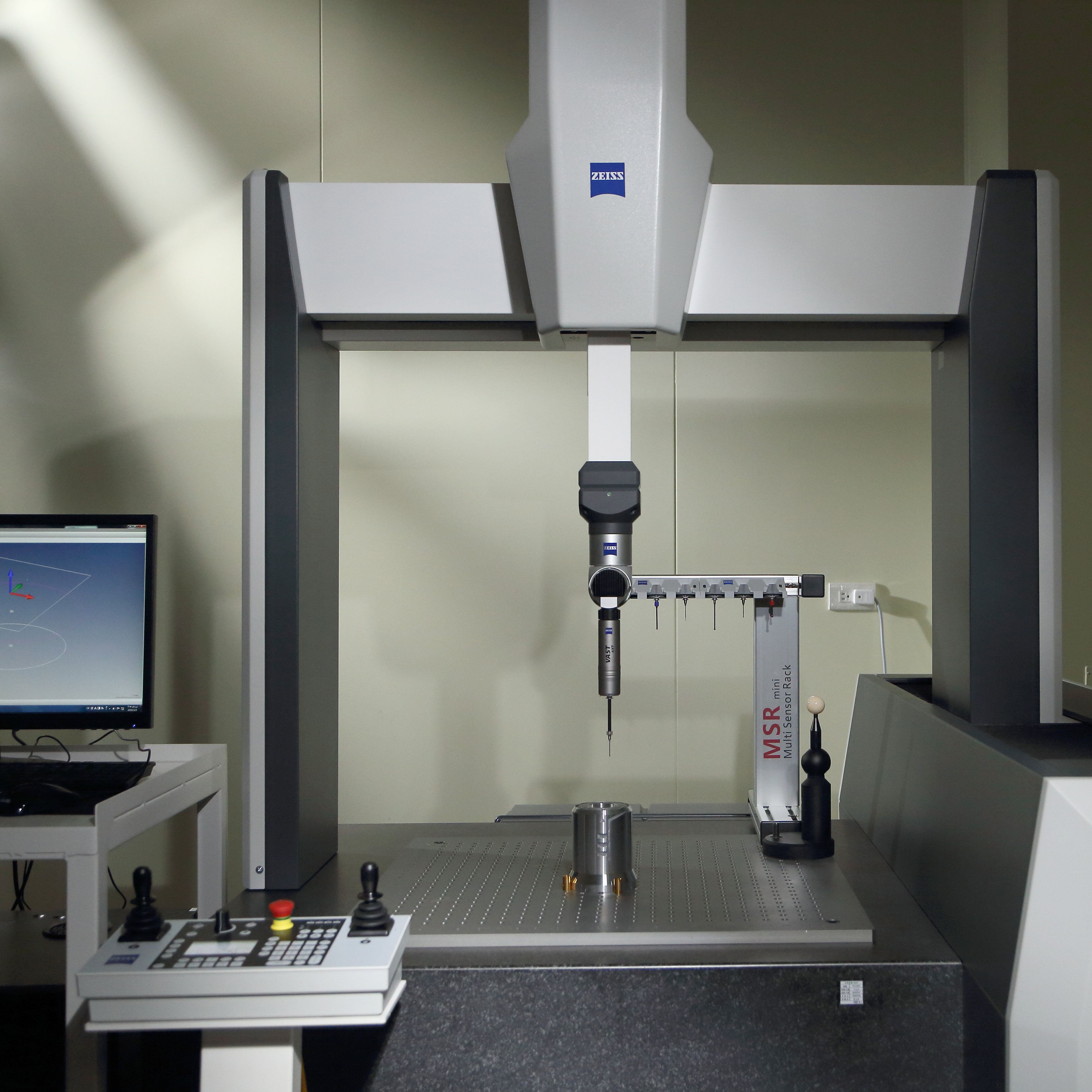

- Coordinate Measurement Machines (CMMs)

- Surface Tester

- Hardness Tester

- Microscope

- Profile Projector

- Runout Tester

- Torque Tester

- Force Gauge

- Density Meter

- Rotary Accessory Functional Tester

- Environmental Tester

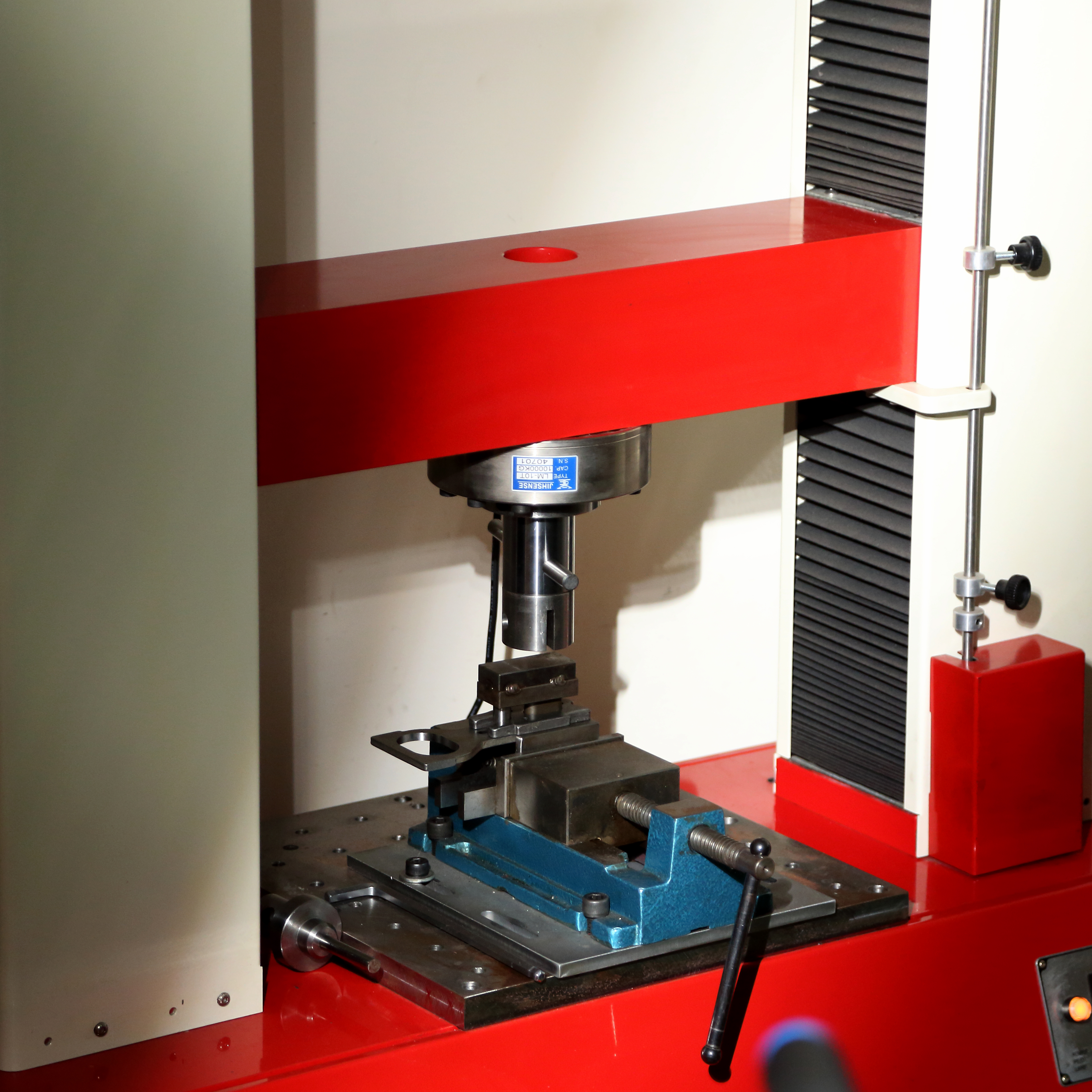

- Universal Force Tester

- Roughness Meter

- Hi Pot Tester

- Micrometers and Gages

- Air Gages